Elastomers and synthetic fibres

An Elastomer is a polymer with the physical property of elasticity. Elastomer is a term derived from elastic polymer, which is often used interchangeably with the term rubber. Synthetic fibers are a subset of the larger area of textiles.

Textiles can be natural or synthetic. Natural fibers include cotton, fur, wool, etc.

Regenerated fibers are natural materials that have been processed into a fiber structure. Regenerated fibers such as cellulose and wood pulp are used to make materials such as rayon and acetate.

Elastomer

the elastomer means "rubber". There is some polymers which are elastomers include polyisoprene or natural rubber, polyisobutylene, polybutadiene, and polyurethanes. The Elastomer materials are those materials that are made of polymers that are joined by chemical bonds, acquiring a final slightly crosslinked structure. The characteristic of elastomer materials is the high elongation and flexibility or elasticity of these materials, against its cracking or breaking.Classification of elastomers

- Thermoset Elastomers : The thermoset Elastomers are those elastomer materials which do not melt when heated.

- Thermoplastic Elastomers : The thermoplastic Elastomers are those elastomers which melt when heated.

Properties of elastomer materials

- The elastomer materials are generally insoluble.

- The elastomer materials are flexible and elastic.

- The elastomer materials can not melt, before melting they pass into a gaseous state.

- The elastomer materials swell in the presence of certain solvents.

- The elastomer materials lower creep resistance than the thermoplastic materials.

Examples of elastomers adhesives

- Adhesives based on silicones.

- Adhesives based on modified silane

- Polyurethane adhesive 2 components.

- Polyurethane adhesive by curing 1 component moisture.

Examples and applications of elastomer plastic materials

| Natural rubber | material used in the manufacture of gaskets, shoe heels and etc. |

| Polybutadiene | The elastomer material used on the wheels or tires of vehicles, given the extraordinary wear resistance. |

| Silicone | The silicones are used in the manufacture of pacifiers, medical prostheses, lubricants, mold, etc. |

| Neoprene | The material used primarily in the manufacture of wetsuits, which is also used as wire insulation, industrial belts, etc |

| Polyurethanes | The polyurethanes are used in the textile industry for the manufacture of elastic clothing such as lycra, wheels and used as foam |

Synthetic Fibers

Synthetic fibres are used for making clothes and many other things. The synthetic fibres may be entirely synthetic or semisynthetic. Semisynthetic fibres, like rayons, are made by using natural polymers as the starting material. The Pure synthetic fibres are made from chemicals. Polyesters, nylons and acrylics are purely synthetic fibres.Material Properties of Synthetic Fibers

| Composition and structure | The type of polymer, the amount/length of side chains, and the shape of the polymer. The strength of the polymer depends on the shape and amount/length of side chains. |

| Melting point | The temperature at which the polymer starts melting. This is improved with the presence of high molecular weight tail or long chain branches. |

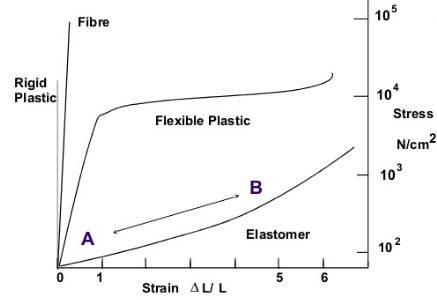

| Elasticity and recovery from strain | The elasticity limit is the stress at which the uni-axial stress-strain curve becomes nonlinear due to crazing or shear yielding. the crazing is the formation of low density and shear yielding is the irreversible slipping of molecule chairs. |

| Density | The density affects physical properties like stiffness, impact strength, and optical properties |

| Dye-ability | The ability of the polymer to absorb and hold on to any dye |

| Moisture absorption | The amount of moisture a fiber will absorb from the air at a standard condition of 70°F and a relative humidity of 65%. |

| Modulus | The ability of a material to resist deformation. |

| Comfort | How the material feels to the user, freedom of movement when wearing the fabric, phase change ability, and hydrophobic nature should be considered. |

Advantages of Synthetic Fibers

- Strong

- Thermoplastic

- Resistant to moths and fungi

- Easily available

- Abrasion-resistant

- Easy to care for

- Low absorbency

Disadvantages of Synthetic Fibers

- Melt when hot

- Non-renewable

- Can be an allergenic

- Use petrol

Specifications Synthetic Fibers

There are different requirements based on the fiber's application. Two general application categories are apparel/domestic and industrial.

For industrial applications the fiber must have a tenacity of 7-8 graddenier, have 8-15% elongation at break, a modulus of elasticity of 80 graddenier or more conditioned and 50 graddenier when wet, as well as a zero strength temperature of 250°C or above.

ThicknessSynthetic fibers can be extruded to different thicknesses called a denier. Thickness of a fiber also refers to its diameter or distance across the fiber's cross section.

Synthetic fibers have a uniform diameter because it can be controlled during the manufacturing process. The opening in the spinneret is responsible for the diameter of the fiber.

WidthThe overall width refers to the outer diameter or cut width of a roll of fabric of textile material.

LengthFabrics and textiles are sold in roll form at varying lengths, many in excess of one mile.

Break Load (Rope/Fiber)

Breaking strength is the maximum tensile load or force that a rope, cord, webbing, or fabric will hold before breaking.

Applications

Synthetic fibers and synthetic fabrics are used in a variety of industries and applications, including:

- Marine

- Aerospace

- Welding

- Architecture and construction

- Electronics

- Automotive and transportation

- Electrical

- Apparel or clothing

- Filtration

Go to index page